Insights

5 Crucial Steps for Conducting a Post-Incident Debrief

A structured debrief allows facility teams to pinpoint what worked, uncover weaknesses, and refine protocols to turn every incident into a learning opportunity to improve response times, reduce downtime, and enhance overall confidence and preparedness.

Leadership vs Supervision in Facility Management: Why Both Matter

Understanding the difference between leadership and supervision – and how to develop skills for both – can help facility managers optimize team performance, improve response times, and optimize facility maintenance and overall facility operations.

Ready When It Counts: Tips for Equipment Storage

Ensuring rapid water damage response starts long before an incident happens – it requires strategic planning for both fixed and mobile equipment placement, especially for large facilities spanning multiple acres. Learn how to plan for and place equipment for flooding emergencies.

Three Bonus Benefits of Water Damage Training

Having a team ready to respond to water events in-house immediately benefits your facility with faster response time, reduced damage, and lower repair costs. But there are several often-unexpected benefits that make water damage training a valuable investment for facilities teams.

Ready, Plan, Adapt: Facilities Management’s Expanding Role

Learn about the changing expectations for the facility manager's role - from overseeing smart building systems to managing security risks, plus safeguarding building assets and preventing water damage disruptions to operations and occupants. Through it all, facilities teams must be proactive and strategically address gaps in preparedness.

Wildfire Smoke and IAQ: Air Filtration Strategies for Facilities

Maintaining indoor air quality (IAQ) is always critical for facilities teams. With increasing incidences of wildfire smoke, it's important to learn how best to remove smoke particulate matter and smoke odors to prevent health risks for occupants and workers.

Frequent Water Damages: The Hidden Costs to Your Facility

Optimizing Dehumidifier Placement for the Best Results

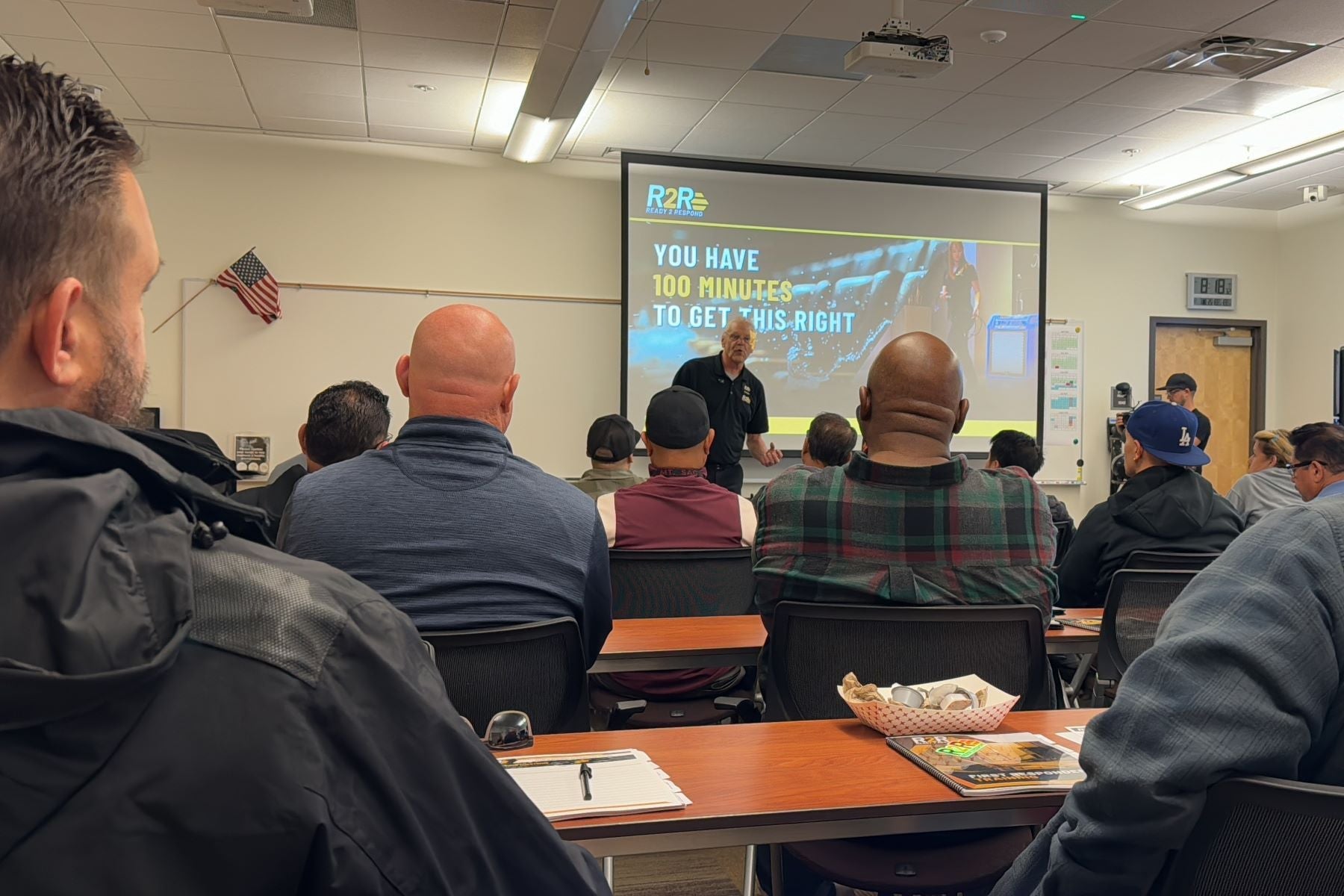

Team Training: Essential Skills for Water Damage Response

The true key to successful water damage response lies in cultivating a skilled, knowledgeable team that knows how to operate equipment and how to assess damage, prioritize safety, and communicate effectively under pressure. Learn the core skills facilities teams need for faster water event recovery.

Staffing Smart over Winter Breaks

Freezing temperatures, snowstorms, and icy conditions can cause burst pipes and water damage which demand immediate attention. Here's how to set a solid staffing plan for weekends and holiday breaks to avoid having minor issues escalate into costly problems.

Winter Checklist for Maintaining Drying Equipment

Case Study: University of Tennessee Knoxville’s Water Damage Response Transformation